The composite materials created by the defense industry developed in the yacht building sector (the radar being one of the first applications) are now also applied, both as product ánd technology, in the shipbuilding industry.

The advantages offered by these newly available construction technologies are remarkable, considering what they offer in terms of weight reduction and formal constraints and how the risks related to smoke and flame spread in case of fire, which are particular to non-metallic materials and are common in the air and rail transport sector, is severely reduced. Especially the lightness and strength of these composites is what makes them irreplaceable in the shipbuilding industry.

Trends in carbon

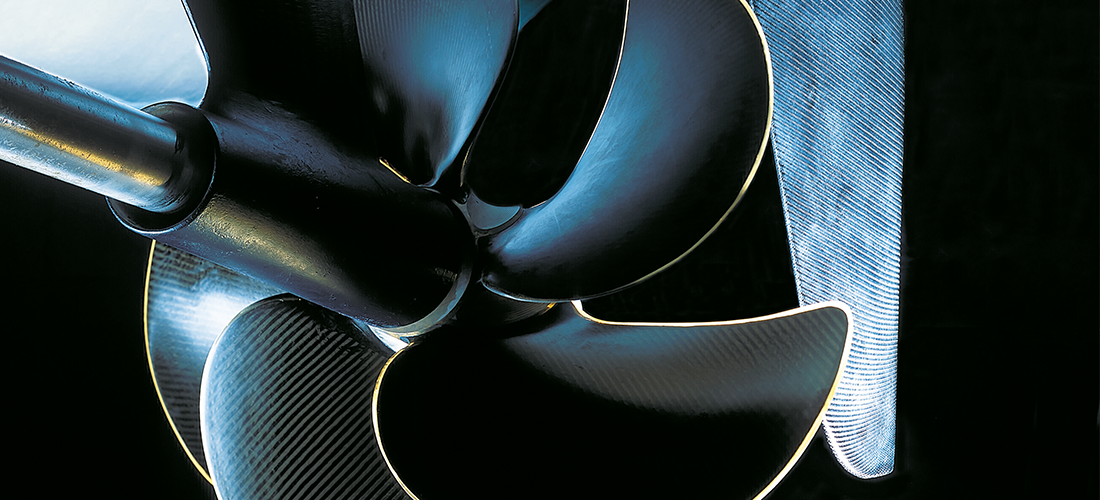

It’s interesting to see how the use of advanced composite materials in the marine sector has evolved over the years. We have moved from the discreet, thrifty use of carbon UD fibres (also due to the fact that the cost of carbon fibres have lowered significantly in the past few years), to the massive use of laminates, skins of sandwich structures and carbon fibre hulls. This is essential in race boats, in structural pieces of specific use, such as components or hydro dynamic appendages. On the other hand, one needs to watch our for inappropriate use of carbon fibre, for example the so called ‘carbon look’, which is merely a skin placed over a GRP made product.

Carbon fibre is also indispensable in the case of UD-C flat bars with core in biaxial carbon reinforcements +/- 45 °. This counts for almost all transversal and longitudinal reinforcing structures. Glass/carbon is also used to reduce carbon costs.

Another current trend is the use of multiaxials + 90 ° / 0 ° or +/- 45 ° and relative combinations of carbon only. The multiaxials improve the flow of the resin, increase the mechanical characteristics with the same weight of the reinforcement in the stratified compared to the conventional fabrics. Conventional fabrics that have their own logic in particular weaving styles such as twill which, thanks to their characteristics of drapability, are used in areas with complex geometries.

The all carbon simplifies the structural calculation and the verification of the potential mechanical characteristics of the product.

Materials are not everything

Of course material is not everything; we need appropriate design, geometry, attention to detail and experience. Marine design means hull lines and design setting but also the structural aspect of the project. Also, a good designer is not the one who uses materials with superior mechanical characteristics, but the one that obtains high results with average materials. Structures are optimized by making the most of geometries and shapes. However, the ability to get the best compromise between costs and performance is rare nowadays.

To build a boat does not just mean putting together materials but having knowledge in the structural field, before building one must design and calculate. A boat can be constructed very well but can be, if poorly designed and miscalculated, very unsafe.