What’s the definition of ‘slamming’? According to David K Brown’s 2010 book The Grand Fleet, Warship Design and Development 1906-1922: Slamming is a large flat area of a hull hitting the surface of the water with force all at once. It can involve many different sections of a hull depending on its shape and is taken into consideration when designing ships. The author asked two well-known composite experts and structural engineers, Valerio Corniani and Luca Olivari, about their ideas on this topic.

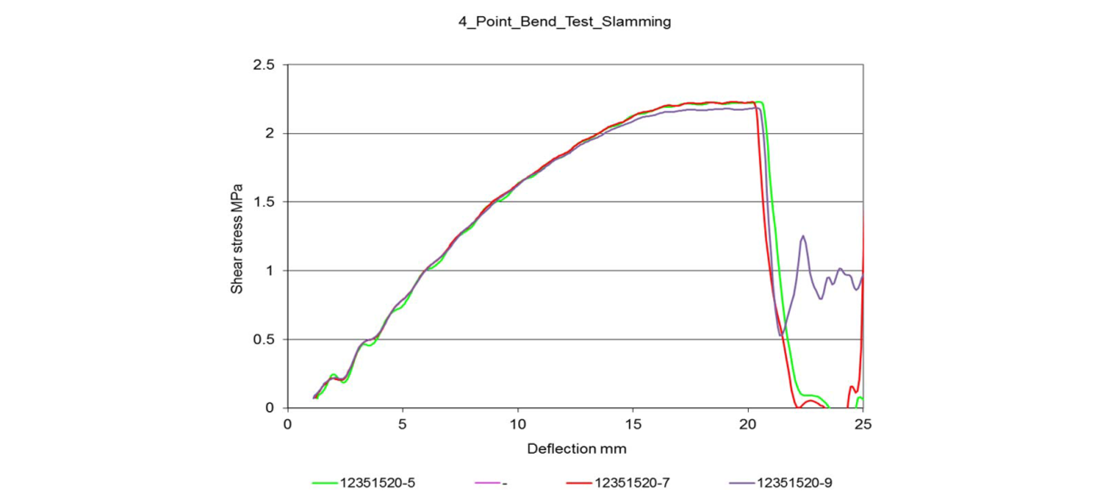

Valerio underlined that the first thing to keep in mind is the need to distinguish carefully between static and dynamic loads. Static loads have a steady, fixed and usually known value applied over a significant time. Dynamic loads, on the other hand, are often of short duration, characterised by maximum values that can vary significantly, and difficult to define and quantify. They depend on vessel speed, wave height and vessel shape.

StaticFoil

Slamming represents a dynamic load on a vessel. The energy it produces is absorbed by both the water and the hull structure. The scope and proportion depend on hull size and shape, vessel speed and, of course, sea state. Slamming loads are increasingly becoming larger, because vessels are going faster than ever before and vessel bottoms are becoming flatter.

Valerio Corniani, a composite engineer and global marine segment manager at Diab, affirms that he cannot tell a naval architect to design a hull with a V shape to reduce the loads. The lines of a hull are designed to suit a particular purpose and, as a composite engineer, he has to design a structure which suits the loads affecting that hull shape.

Hull structure

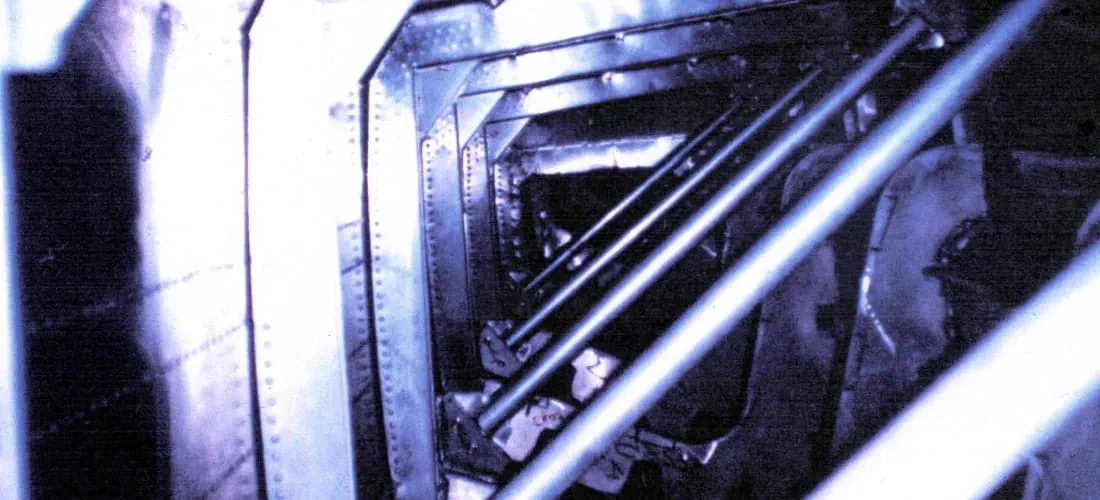

Valerio focuses on sandwich constructions and on the different materials such as sandwich panels, sandwich I-beams and sandwich-to-single-laminate junctions. These elements are what make the extreme lightness and stiffness of the items possible. Sandwich panels owe their strength to the combination of skins, which resist the bending loads, and the core, which takes the shear loads.

Loads in a sandwich panel

Luca Olivari of Olivari Composites is a naval architect and one of Europe’s major experts in composite materials engineering. He has been dealing with the challenge of slamming since 1990, when he began the structural project for a carbon composite class 1 powerboat. The first question he asked himself was how best to define the dynamic pressures acting at the bottom of the hulls for a boat running at 160 mph. How should the slamming phenomenon be managed?

No classification register had yet defined a rule to evaluate the pressures affecting the bottom of high-speed racing boats. At the time, however, Michael Peters was designing the fastest class 1, which was to be built in aluminium by the CUV yard in Viareggio. Knowing the size and thickness of the panels made it possible to calculate the pressures that would cause yield stress on the aluminium. These pressures were found to be very high, corresponding to decelerations of more than 10 G.

Calculating the pressure

As this is a range of acceleration that cannot be withstood by humans, the conclusion was that these pressures were felt during milliseconds and the relative energy was dissipated within the boat structure and not transferred to the pilots, leading to the slamming phenomenon. Based on these assumptions, Luca calculated the pressure distribution on the bottom and the tunnel of the boat.

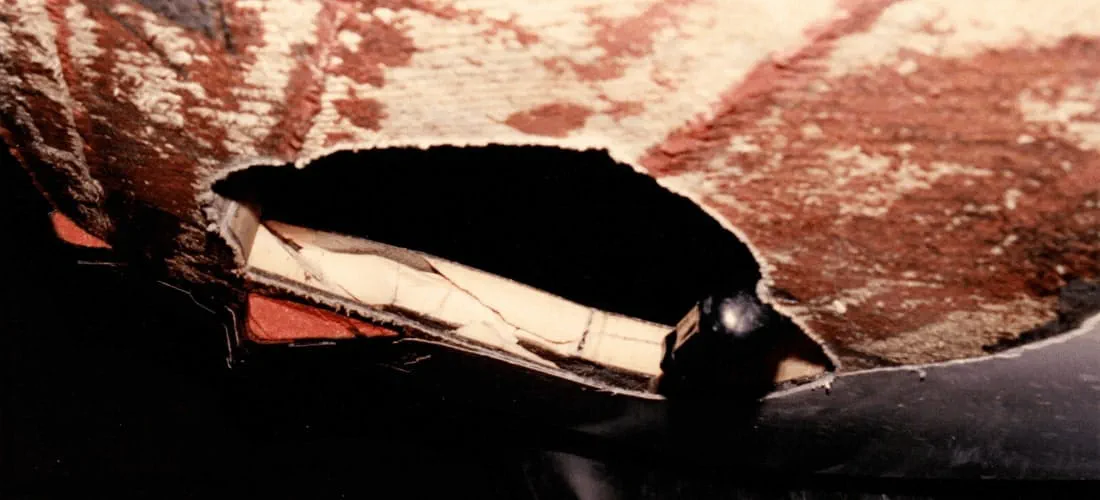

Slamming is common to powerboats, but also light and fast sailing monohulls and multihulls. The typical damage initially appears through the outer and/or inner skin delaminating close to the internal structure. If slamming continues, the core eventually explodes completely across the entire panel. At the time, Diab was developing and testing a special core for the Swedish navy. With a density of 200 kg and shear elongation of 50%, this core was ideal for the class 1. Diab fatigue-tested a sample of this core, never reaching shear breakage before the skins.

From this point on, there was a constant evolution, boat after boat, of pressure intensity and distribution. The first relevant project was the class 1 Giesse-Iceberg designed by Michael Peter and built by Tencara for Ferretti in the 1992 in carbon/nomex/epoxy prepreg composites, which won the 1994 World Championship.

Checking the structure of the award winning boat, Luca discovered that the bottom panels of the hull where permanently deformed, showing deflection of up to 3 mm.

“Composite materials are fantastic, but they are still weaker than metals in many ways,” Luca points out. In composite materials, tension and compression stress is best harnessed when aligned along the fibre of the laminate. If the pressure suddenly changes direction in relation to the orientation of the fibres, however, it turns into shear stress.

“Unlike the tensile and compressive pressure resisted mainly by various fibre reinforcements, interlaminar shear stress falls on the matrix resin. The matrix is nowhere near as strong as the fibres and has relatively low fatigue strength. This also applies to foam cores, which are basically expanded resins. Knowledge of all these concepts is fundamental to managing a project for a fast carbon hull the right way. The correct definition of design pressures for modern sailing yachts remains an open problem.”

Slamming is also related to the ability of a structure to absorb energy. The more rigid a structure is, the greater the impact force caused by slamming. It's like the difference in landing from a jump on bent or outstretched legs. If slamming occurs in the middle of the panel, the panel flexes and the skins bear the resulting tension and compression. As flexion is a very effective way to absorb energy – the skins are not overloaded even if a great deal of energy has to be absorbed.

If the slamming occurs at the edges of the panel, however, the material cannot flex because it is close to the supports. The only way for the energy to be absorbed is through shear deformation of the panel. This is not very effective for absorbing energy (the shear stress generates little displacement) and in a sandwich, the shear stress is taken on by the core, leading to increased risk of deformation. It can also happen that the core is of high deformability and can absorb a lot of energy thanks to its ductility, but the skins sometimes fail to stick to the core when it deforms a lot. The skins then separate from the core, the structure no longer works as a sandwich and the panel breaks. In this case it is the "fault" of the skin that has not been able to follow the deformation of the core and has detached itself.

However, it is now clear that with the appropriate choice of resins, additives, reinforcements, core materials, fillers and coatings, fibre reinforced polymer (FRP) composites can be used to make boats structures with better performance benefits over many other materials, in addition to other benefits such as weight reduction or corrosion resistance.