As I start to write this article, I have to admit to a fairly long-term fascination with the concept of propelling a boat along, by using the very water that it floats in as the motive power. However thus far, hydro-jet propulsion has usually proved to be a fuel heavy concept. So, is that about to change with new technology?

Over 20 years ago, when I first started living in the Netherlands, I was a frequent passenger on the water jet propelled Stena HSS, the high-speed ferry to Harwich in the UK. It took just over 3 hours to cover the 150 miles across the North Sea, and zooming along at over 40 knots, on such a large vessel, carrying up to 1500 passengers and 375 cars, was always a something of thrilling experience. Quite apart from the satisfaction of getting to the destination so much faster. Unfortunately, the three HSS ferries that Stena operated have now been decommissioned. The reason being, that they were economically unviable due to their heavy fuel usage, a bit of a Concorde aircraft type story!

Several years later I met and became friends, with Captain Guy O'Connor, who was for some time the skipper of the yacht belonging to the King of Spain. MY Fortuna was a 41.5 metre water jet propelled motor yacht, most definitely built for speed! She was powered by twin 1,280hp MAN engines and triple Rolls Royce 6,700hp gas turbines, coupled to three Kamewa water jets. Guy had been the build captain at the yard, and would always proudly enthuse about the performance of the yacht, which had a top speed of 70 knots; quite a breakthrough for a boat of this size, considering that she was launched over 20 years ago now. Fortuna is no longer under the Spanish Royal family's ownership, for similar economic reasons, and with the King not wanting Spanish citizens to regard him as too decadent, being seen to be pouring money into his super-fast Superyacht’s fuel costs.

How does water jet propulsion work?

Water jets have often been installed in fast ferries and smaller workboats in the past. There are several different manufacturers, for example Kamewa as in the case of MY Fortuna, and a wide range of jets is available. However, one thing they have in common is their high outflow velocities. The installed power of these systems can range between 500 kW up to 25 MW.

The principle of the hydro jet is that seawater passes through a nozzle where an axial pump is located. A considerable jet of water is impelled backwards through the aft pipe system. In the forward mode, the water jet propels the vessel, sometimes up to very high speeds as already mentioned. And a ‘reverse bucket’ principle is employed to effectively block and redirect the flow of water at a suitable angle, in order make the boat go astern.

When water jets are installed in pairs, maneuvering in tight spaces is very easy, with one jet pushing forward, and the other pulling backward.

(Source of info: ‘Comparison of water jets and conventional propeller jets.’ By Henk Verheij - Deltares & Delft University of Technology.)

Electric/hybrid water jets for recreational boats

Just recently, two water jet producers, both based down under, have released details of new electric / hybrid systems they are bringing to the market, no doubt recognising the growing demand for more energy efficient propulsion systems. New Zealand based HamiltonJet was started nearly 70 years ago by the inventor of the water jet propulsion system Sir William Hamilton, and has been producing waterjets for all types of vessels ever since. So, it’s not surprising that they have now taken the step of venturing into the electric / hybrid market, considering the focus on zero or reduced emissions that is sweeping through the boating industry.

As concluded by others, HamiltonJet have taken the view that there is no ‘one-size fits all’ solution, when it comes to adding electric drive to marine vessels. And whilst all-electric is attractive for shorter runs, hybrid is still the way to go for the immediate future, offering the best of both worlds. For low speed silent running, electric power can be selected, with higher speed longer range cruising still possible utilising the diesel engine, but with smart technology minimising the IC engine run time, and optimising the overall fuel efficiency.

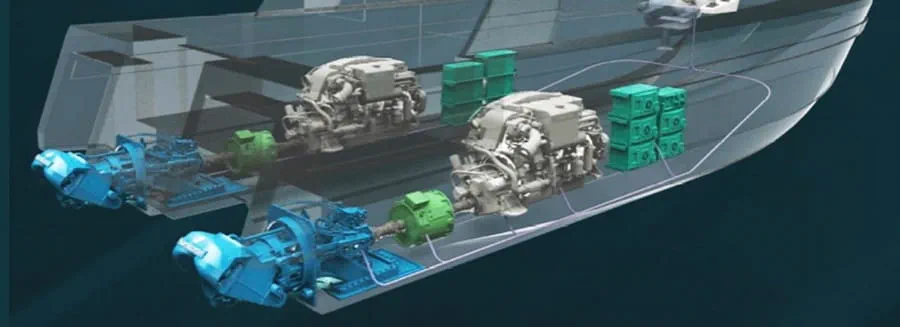

With this principle in mind, the company have launched their EHX water jet propulsion system where they provide electric motors, power electronics and the control system, alongside specialist expertise to ensure seamless integration with the waterjets, engines, gearboxes or clutches.The control system manages the hybrid energy flow between engines, batteries and motors while charging and discharging the batteries as required. And a simple automatic setting enables vessel operation in a manner that they claim is similar to driving a hybrid car.

Meanwhile Australian waterjet specialists Doen, have come up with a different approach to integrating a hybrid propulsion solution. They are now able to supply a hybrid-ready waterjet unit from their range, which incorporates a Power Take In (PTI) concept. This is equipped with a clutch to accept an electric drive input. The electric motor can then be engaged or disengaged as and when needed, thus creating a means of combining and switching diesel and electric power to the waterjet. Doen are also able to provide what they call the ECS400 Control Platform to support their Hybrid-Ready waterjet package. This is readily able to interface to the electric motor, the electric power management system and the diesel engine, thus ensuring that the distribution of power is managed seamlessly. From the skipper’s point of view, the propulsion and control at the helm remains unchanged, with the switching through electric, diesel or hybrid options taking place automatically.

Are you thinking about new, innovative and eco-friendly methods of propulsion? Then don’t miss the range of exhibitors and presentations at the I-nnovationLab during METSTRADE 2020.