With the development of hybrid and electric propulsion systems gathering pace over the last few years, the high degree of focus on fuel savings and emission reductions was more evident than ever at METSTRADE 2019. But what about the piece of apparatus that actually drives the boat? Spinning away, out of sight, and mostly out of mind underwater; is it time for a revolutionary rethink about the configuration of the humble hard-working propeller?

As an essential component of most power-driven vessels the propeller is still a basic piece of technology that has evolved over time to deliver thrust and forward motion to powered boating. Apparently, its origins are in the art of ‘sculling,’ and anyone who has sculled a small boat will be familiar with the ‘figure of eight’ motion required to propel it forward, an action which the rotation of the propeller blades basically mimics.

We all know that careful selection and good maintenance of our prop can ensure that our boat performs at its optimum capabilities, but due to the simplicity of its design and functionality, it may have been thus far overlooked when it comes to significant technological improvements that can deliver better performance, combined with lower fuel consumption.

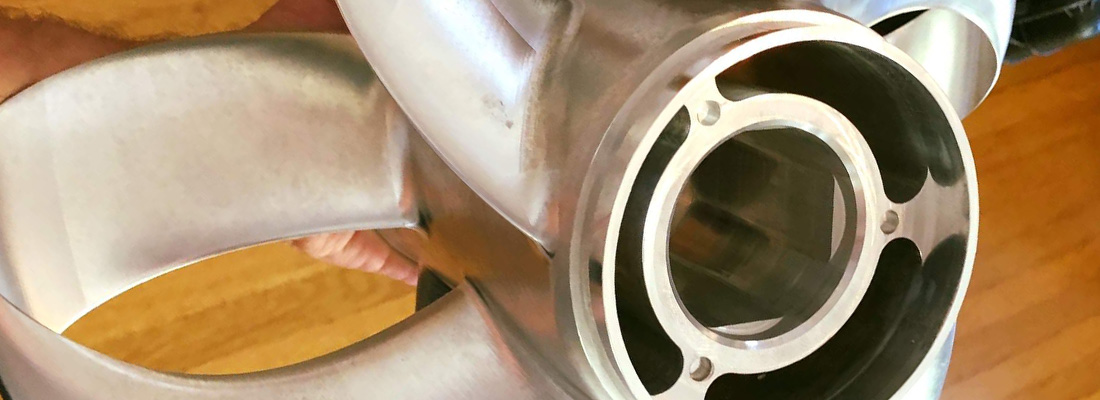

The Sharrow Propeller concept.

Step up inventor and entrepreneur Greg Sharrow, a man who has designed and patented an entirely new design of propeller, which certainly looks very different to anything seen before, and apparently delivers some attractive performance, and ultimately environmental advantages through fuel savings, according to independently monitored test results.

Greg has an interesting back story, as he didn’t originally set out to invent a new propeller. In fact, he was a music college graduate, who was working in the field of video production, and looking for ways to develop an ultra-quiet drone for use in the entertainment industry, where unwanted noise is a critical demand. His starting point was to find a way to reduce or eliminate tip vortices, which he believed could significantly reduce the noise that is produced by propeller rotation.

Tip vortices are known to contribute significantly to drag, noise, and vibration, and this physical fact has been recognised for a long time with wings, and at the tips of propellers both in air and in water. Consequently, over the years, aeronautical engineers and naval architects have tried various propeller designs with modified tip properties, in an attempt to reduce the problem. But Greg claims that none of them have reduced the amount of tip vortices like his Sharrow Propeller™.

As with all inventors there was a ‘light bulb’ moment for Greg when he was out for a morning stroll, thinking about how the tip of a propeller is the cause of the vortex phenomena that ultimately reduces its efficiency. The obvious conclusion to this, was to find a way to eliminate the tip! But how could you make a tip-less propeller? What would it look like and how would it function? Following that inspirational moment, he began assembling the legal and engineering expertise, partnerships and funding, for the massive R&D effort that would be needed to turn his idea into reality. This included an extensive research and testing program with the University of Michigan’s Marine Hydrodynamics Laboratory. And 7 years later, came the all new Sharrow Propeller, designated model MX-1.

How does it work?

Basically, a standard propeller produces a concentrated tip vortex which induces energy loss and a source of cavitation, but the Sharrow Propeller quite simply, has no tip, and thus no tip vortex! This differential has been proven with underwater video images showing a conventional propeller running alongside a Sharrow Propeller. On the conventional prop it can be seen that the "bubbles" coalesce into the typical helical paths from each blade, visibly demonstrating that the tip vortex is present. (It should be noted, that tip vortex cavitation (TVC) is not directly a function of tip speed, but more of blade loading.) However, on the Sharrow Propeller™ there is no tip vortex cavitation visible on the video images.

Test results prove the theory

To answer the question of whether this new design concept will work well on small recreational powerboats, a rigorous testing program was carried out by independent consultants boatTEST. The test boat was a very commonly used, 20ft (6.21m) Bayliner bowrider, and BoatTEST claimed that the testing procedure was the most rigorous they have ever used; pointing out that even a 1% improvement in prop design gives a significant advantage.

The testing team used two conventional ‘benchmark’ propellers, as a direct comparison with the Sharrow MX1, and each was used on long test runs across a range of RPM’s. Once the boat was running at a steady rate for several minutes they recorded RPM, speed through the water, and fuel flow data. The data was then extrapolated to produce a detailed analysis of fuel economy, for a given speed through the water, and a table produced showing results for each of the three propeller types under test.

A summary of conclusions regarding the comparative performance of the Sharrow Propeller versus the other props under test is as follows:

* Performs significantly better at idle / * Planes at a lower RPM / * Faster at all RPM settings / * Significantly more mpg at 3000 and 3500 RPM / * More fuel efficiency at every speed-through-water setting / * As much as 18% more fuel-efficient at 26-28 MPH / * Produces the highest top speed, and the longest range at all speeds / * Also generally quieter and displays superior handling with less vibration.