Rapid development of battery and fuel cell capacities

New scientific discoveries are rapidly embraced to enable more long lasting power to drive electric vehicles. New materials and technology to store electric energy in batteries offer a considerable gain in range for such vehicles. The efficiency of harvesting energy from solar panels as well as the efficiency of hydrogen fuel cells is improving in a rapid pace. Boats and yachts equipped with long life, long range batteries and modes of creating their own electric power, offer stress free navigating for their crews.

Candela, the Swedish manufacturer of electric hydrofoil yachts and passenger vessels, demonstrated the distance their C8 model can cover in 24 hours in their ‘Electric Endurance Challenge’. The hydrofoil boat, seating up to 8 persons, covered 420 nautical miles in 24 hours. That is 777 kilometres, like driving from Paris to Turin in Italy (or from San Diego to San Francisco, roughly). The previous range record was 79 miles (ca. 127 km) in 20 hours. The foiling motor yacht was recharged with a fast charging installation 20 times during the record attempt. Starting off a jetty in Stockholm, the Candela rounded the Tynningö island in the archipelago next to the Swedish capital in a 20 nautical mile lap and then recharged at the Stockholm home base. Norwegian charging station developer Plug provided the charging solution, using a Northvolt battery system due to low grid capacity. Northvolt backup batteries provide a high charging current, that was able to recharge the onboard batteries of the Candela C8 from 13 percent after each lap up to 66 percent in 18 minutes. Using a battery, insufficient power at the local electricity grid is increased by the additional power. After charging the boat with high current, the battery can reload from the grid. On its foils, the Candela was sailing at speeds up to 27 knots. Considering the time it took to recharge the batteries over the whole period, the average speed in 24 hours was 17 knots.

1000 km on a single charge

A student team of the Technical University of Delft (the Netherlands) demonstrated their solar all-terrain car ‘Stella Terra’ in the Sahara dessert by driving 620 mile (nearly 1000 kilometres) on a single battery charge. The roof is clad with solar panels, recharging the batteries even while the car is driving, extending the range. “We explore the boundaries of technology,“ says team manager Wisse Bose. “The Stella Terra must withstand the harsh conditions of off-roading while remaining efficient and light enough to be powered by the sun. That is why we had to design almost everything for Stella Terra ourselves, from the suspension to the inverters for the solar panels. The car was actually very comfortable in off-road conditions as it is very light and does not get stuck,” says Bose. “We hope this can be an inspiration to car manufacturers.” Electric automobiles these days are packed with luxury accessories, making them bulky and heavy. All of the weight carried over the roads strongly reduces the positive environmental impact that electric mobility might have.

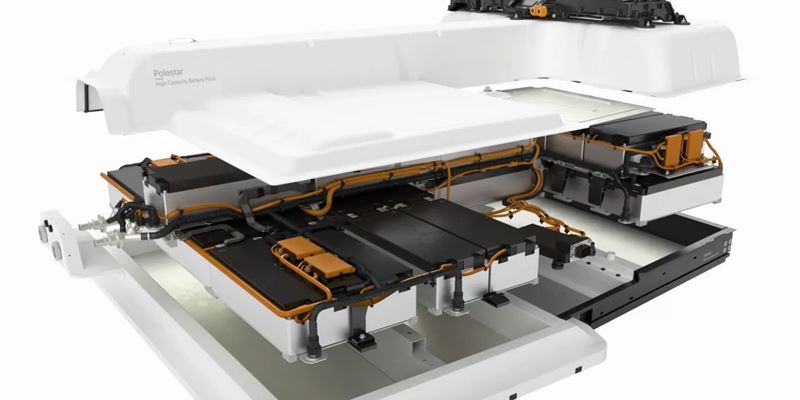

Energy density

Demonstrators and experiments like the ones mentioned, reply to the industry and consumers that need to see their doubts answered about range, safety, durability, and ease of electric propulsion. Exponential growth of the electric mobility market is a good starting point for scientists and engineers to research improvements in providing electric power on board trucks, cars and vessels. Less weight, less volume, more safety and more range are the key points of interest in their studies. Energy density is critical for batteries that drive electric boats and yachts. Battery packs that contain a lot of energy in every kilogram of their weight and in every cubic inch of their volume, can bring a vehicle further at higher speed while taking up less space aboard than their conventional counterparts. After the first decade of widespread change towards electric mobility, big gains are still being made in improving the energy density, longevity, and capacity of the batteries that carry the electric power to drive electric vehicles. Scientists and engineers are still discovering and developing new technologies to improve batteries and enable long range mobility.

Rubber ion highway

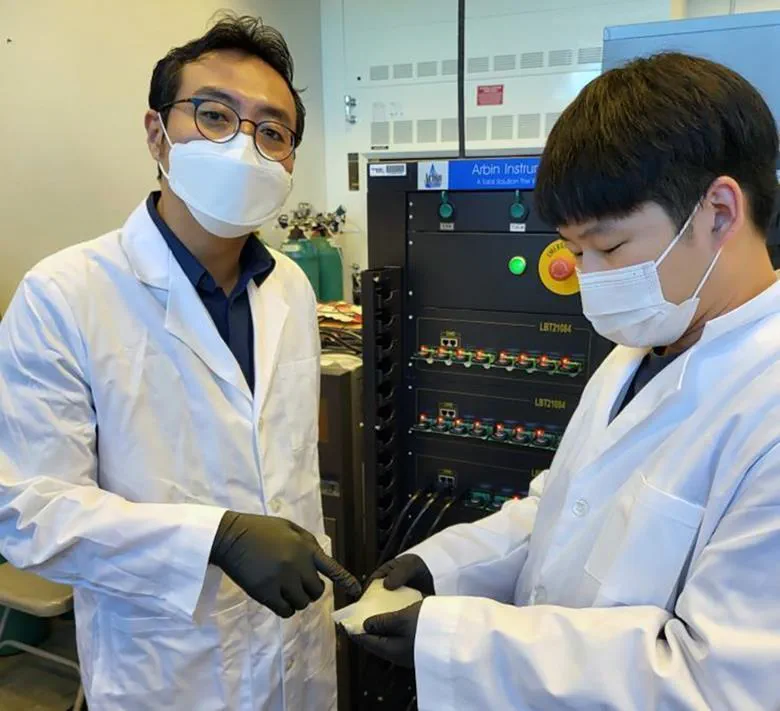

Rubber electrolytes inside lithium-ion batteries could improve the energy density and reduce the risk of overheating, scientists discovered. Using rubber as a conductor seems intriguing, because the natural elastomer is mostly known as an insulation material. A chemically enhanced elastomer, based on natural rubber, will allow for a higher flow of ions inside modern ion-lithium batteries. This new technology solves two problems that modern vehicles face with their batteries: risk of fire and explosion is minimized and poor flow of ions through the conductor fluid is better, improving the energy storage capacity. The improved flow of ions in rubber elastomer was discovered very recent by mechanical engineering graduate researcher Michael Lee of Georgia Institute of Technology and professor Seung Woo Lee, together with scientists from Korea Advanced Institute of Science and Technology. The researchers found that the material, when formulated into a 3D structure, acted as a superhighway for fast lithium-ion transport with superior mechanical toughness. This ion superhighway allows for more electric energy to be charged into a battery. This results in more energy density per cubic inch (volume) and also more energy density per kilogram (weight). As the electrolyte layer between the metal (lithium) is no longer fluid, but rubber, the chances of leaks are eliminated, the changes of shortcuts inside the battery are also practically zero and the lifetime of a battery is improved. Using rubber can result in batteries being safer, containing more energy and cheaper. The use of rubber poses also less environmental impact than the electrolyte fluids commonly used in batteries. The research paper was published in science journal Nature in January this year. Research departments of battery manufacturers around the world are already applying the new technology in their products. Among these are Korean SK Innovations, that is building a new solid state battery factory in Georgia, USA, as well as Swiss manufacturer Datwyler. The solid state rubber electrolyte lithium-ion battery is considered a major breakthrough in battery technology.

Seung Wong Lee (L) & Michael Lee (R)

Curing for electrolyte

Swiss start-up HPB (High Performance Batteries) has developed a battery that will last 10 times longer than a liquid electrolyte Lithium-ion battery. The HPB type of solid state battery creates its own electrolyte after assembly, much like a two component resin does: once both elements are brought together, a chemical reaction starts and in the case of the HPB solid state battery, the electrolyte forms. Prototypes tested showed more than 12,500 charging cycles – ten times the calculated number of charging cycles of a lithium-ion battery. No cobalt is needed in the production of the HPB solid state battery. The company announces production to start late 2023 in eastern Switzerland.

Range extension

More range at affordable price is furthermore enhanced by series produced fuel cells. Hydrogen fuel cells have been long discovered as a source of constant and reliable power with only water coming from the exhaust pipes. Manufacturing fuel cells, with their series of membranes, is challenging and costly. UK firm Bramble Energy found means for more cost-effective production of fuel cells, using the same methods as used for making PCB’s – printed circuit boards. PCB laminates are made from layers of conductive and dielectric (non-conductive) materials and are produced in standard sheets called panels. Because PCBs are found in virtually every electronic device, the panels are mass-produced throughout the world. Bramble Energy has developed its new fuel cells which are constructed using PCB laminating machinery, ready available within the existing supply chain. When series production of the cheaper fuel cells is up and running, they may be modular stackable and provide a cost-effective mode of clean range extension for battery powered electric boats.